Frameless glass showers are a showstopper in any bathroom, shower room, or wetroom. But keeping your glass in good condition can be tricky – especially if you don’t know how to clean shower glass correctly.

The good news is that there’s a simple way to prevent damage or permanent stains and marks: regular, light cleaning with a non-abrasive cleaner. In this article, we’ll explain the most hassle-free way to clean a frameless glass shower, as well as which products to use, which ones to avoid, and even how to make your own shower spray.

Preventative measures

Just like in medicine, prevention is the best cure when it comes to clean shower glass. In this case, prevention means wiping off any soapy build-up from the glass panels after showering. If left for extended periods, soap, and particularly calcium, can cause etching and even permanent damage to your shower glass over time. This risk is especially acute in homes with hard water – use this guide to check how hard the water is in your UK area.

To be on the safe side, you should wipe down once a day, and preferably clean shower glass after each and every use. This doesn’t have to be a time-consuming ordeal – just a minute or two. The important thing to remember is that being disciplined with regular cleaning is the number-one way to prevent damage to your glass.

Using the right cleaning products

Using a non-abrasive cleaner is the safest way to clean shower glass. This is because abrasive cleaners – along with aggressive cleaning chemicals – can damage the glass and metal fittings, staining and scratching finished surfaces.

There are plenty of good non-abrasive cleaner options out there. We recommend one of these three:

- Microfibre Cloths – You’ve probably seen these on supermarket shelves, often branded as an E-Cloth. Microfibre cloths are great for preventing water spots and soap build-up. They are the best way to clean shower glass and also provide advantages over other cleaners by locking in dirt and making hard-to-reach areas, such as corners and door handles, easier to clean.

- Squeegees – A popular choice due to their size, firm handles, and ability to attach to walls using a suction cup. Their long, flat rubber blades usually cover a wider area than cloths, making them quicker to use.

- Non-abrasive sponge – It doesn’t matter what kind of bathroom sponge you use to clean your shower glass – just so long as it is clearly labelled “non-abrasive”. Similar to microfibre cloths, sponges are more versatile than squeegees and are better for cleaning in awkward spaces.

Once you’ve found your weapon of choice, it’s time to pick a cleaning solution. These fall into two camps: off-the-shelf shower cleaners and homemade shower sprays.

For the former, simply use a branded or own-branded shower cleaner, available at any supermarket or corner shop. These don’t need to be specialist products or chemical-intensive cleaners – just a normal daily cleaner. (Please note: this is a general guide to cleaning shower glass. Always ensure chemicals are suitable for the intended use and check with the shower enclosure or fittings manufacturer how to clean components. Chemicals can mark and discolour metal shower fittings.)

If you’d prefer to make a DIY detergent spray to clean shower glass (do not use on metal component without first contacting the manufacturer), you’ll need four ingredients:

- ½ cup rubbing alcohol

- ½ cup hydrogen peroxide

- 1 teaspoon liquid dish soap

- 1 tablespoon dishwasher rinse aid

Put your four ingredients into a 32-ounce spray bottle and fill with water. Gently shake the bottle to let the ingredients mix without creating a foamy mess. And that’s it!

Protecting your shower glass with Clearshield

For the ultimate easy clean shower glass, we can coat your shower screen glass with Clearshield. This is a special polymeric coating applied to the glass while it is being processed and is perfect for showers, balustrades or anywhere glass is exposed to moisture or weather. The coating helps to prevent contaminates from sticking to the glass and causes water to bead and run off. This drastically reduces the build up of soap, dirt and limescale. While the glass and shower will still need to be cleaned, Clearshield makes cleaning much easier and will keep your shower glass looking like new for longer. For more information about Clearshield read our recent article.

What shower glass does abc Glass offer?

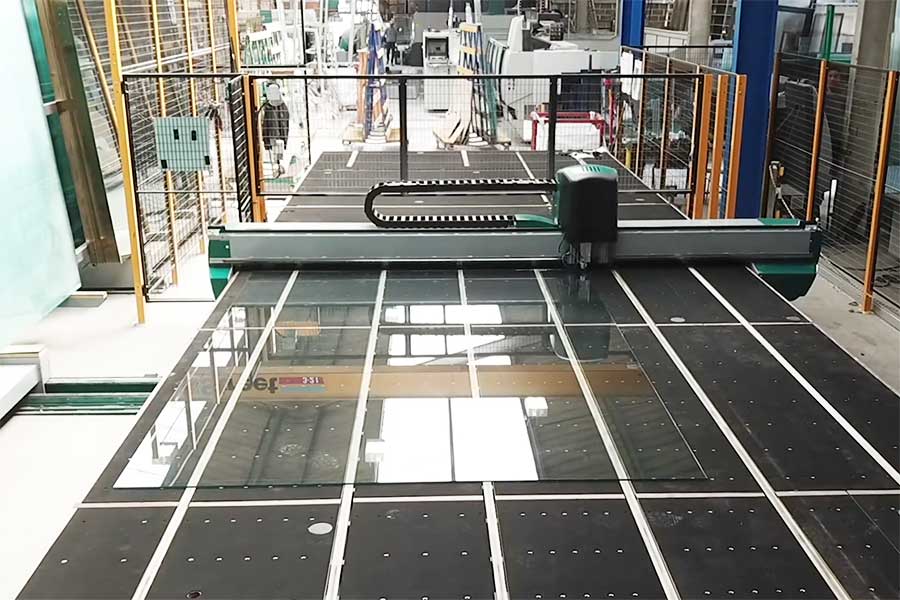

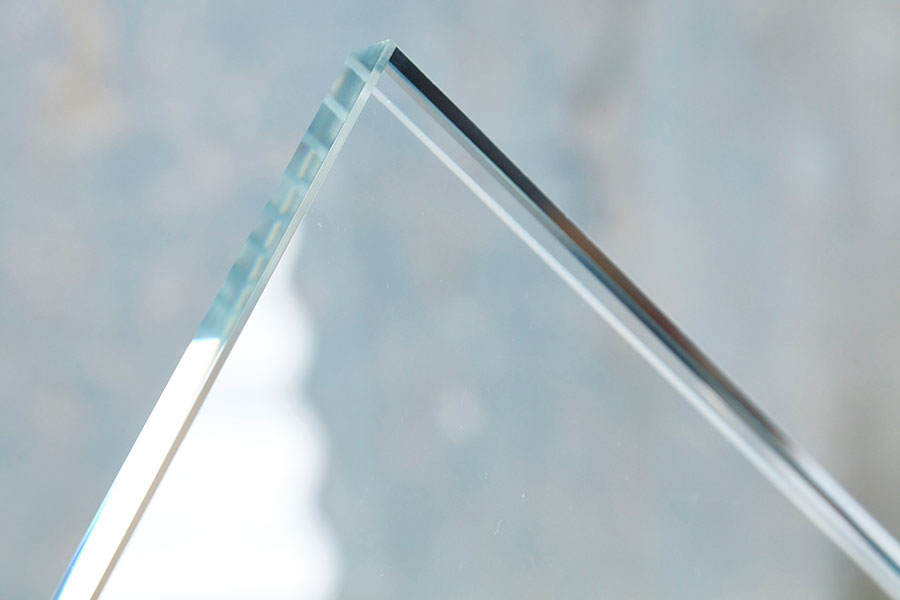

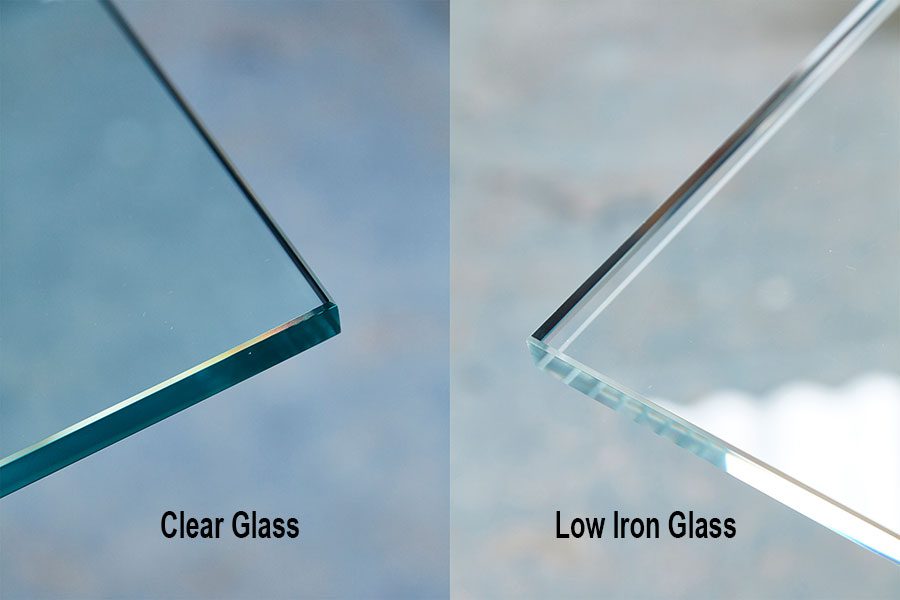

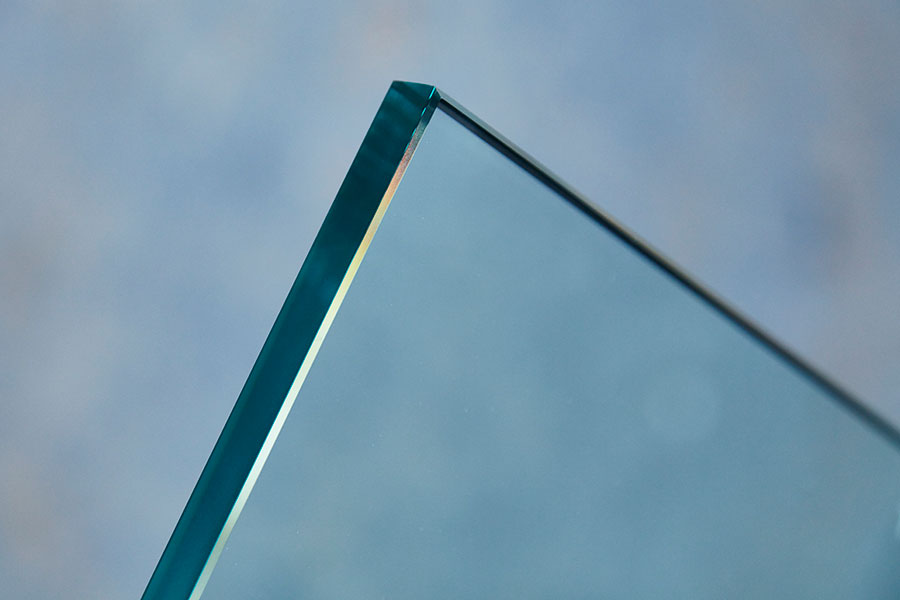

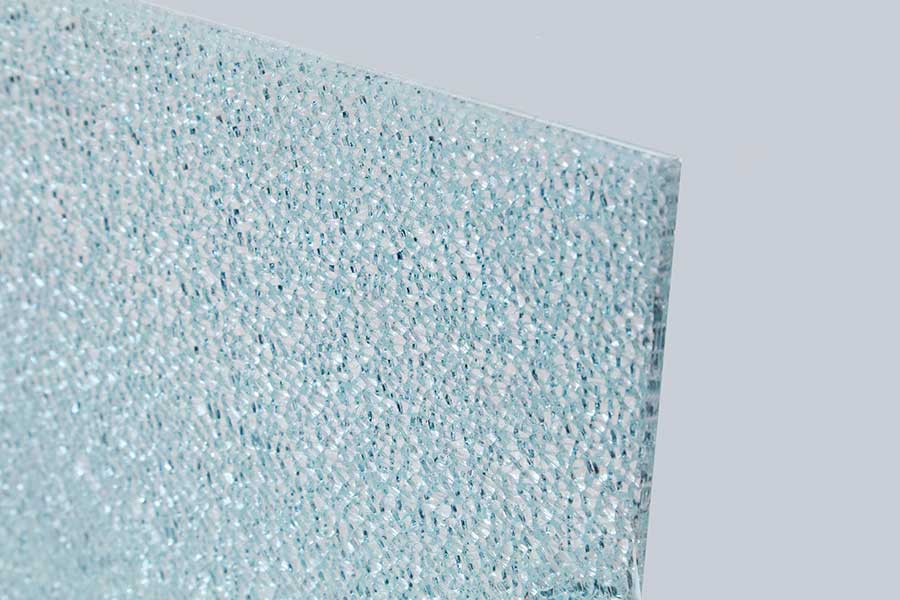

While we do not supply or fit complete showers enclosure or fittings, we do offer high-quality toughened glass panels cut to size in your specific dimensions. Using our CNC machines and water jet technology, we can cut intricate shapes and cut-outs for patch fittings, hinges and door handles. We supply clear, ultra-clear, and sandblasted glass for use in all kinds of frameless glass shower screens, doors and enclosures. Other customizable options include Clearshield glass protection, as well as grey and blue tinted glass. Our glass panels come in a choice of three thicknesses: 6mm, 10mm, and 12mm.

If you have any questions about our glass processing service for frameless glass showers, feel free to reach out via the contact page. Our glass processing experts will guide you through each step and can produce stunning, custom glass shower panels that do justice to your next bathroom project.